Welcome to the Ormet® TLPS Product Portfolio

Ormet® TLPS (Transient Liquid Phase Sintering) products represent cutting-edge technology for electronic assembly and PCB manufacturing. Leveraging patented TLPS technology, these products deliver unparalleled performance in thermal and electrical conductivity, high-temperature stability, and mechanical reliability. Ormet® TLPS pastes are the ideal choice for advanced packaging, high-density interconnects, and harsh environment applications.

Why Choose Ormet® TLPS Technology?

Ormet® TLPS products combine the best features of solder and sintering solutions, making them a versatile platform for a wide range of applications. Key benefits include:

- Low-Temperature Processing: Forms metallurgical bonds at temperatures as low as 180°C.

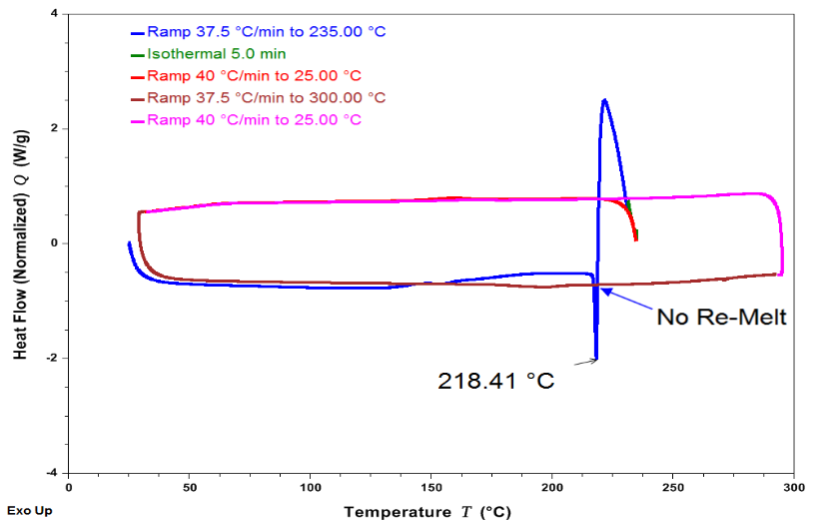

- High Thermal Stability: No remelting below 400°C, allowing for multiple assembly cycles.

- Exceptional Conductivity: Electrical resistivity as low as 20 µΩcm and thermal conductivity up to 60 W/mK.

- Environmentally Friendly: Pb-free and halogen-free compositions that meet global regulatory standards.

- Versatile Application Methods: Compatible with stencil printing, dispensing, and reflow processes.

| Feature | Conductive Adhesives | Solder Paste | Ormet® TLPS-Paste | Ag-sintering | |

| General Property | Process Temperature | 120-175℃ | 190-350℃ | 190-260℃ | 200-280℃ |

| Bonding Mechanism | Adhesive(Chemical bond) | Metallurgical | Metallurgical | Metallurgical | |

| Reaction Process | Box oven | In-line reflow | In-line reflow / Box oven | Thermal compression | |

| Sintering pressure | 0MPa | 0MPa | 0MPa | 10~30MPa | |

| Thermal conductivity (W/m.K) | <10 | 20-60 | 20-60 | >100 | |

| Electric Resistivity (μΩ.cm) | <100 | 10-30 | 10-50 | <10 | |

| Flux Residue | No | Yes | No | No | |

| Will Re-Melt in 2nd Reflow? | No (Tg) | Yes | No | No | |

| Application | Power die attach | ✔ | ✔ | ✔ | ✔ |

| Component manufacture | ✔ | ✔ | |||

| Component attach | ✔ | ✔ | |||

| BGA attach | ✔ | ✔ | |||

| PCB Z-axis interconnects | ✔ | ✔ |

Applications Across Industries

Ormet® TLPS pastes are designed to meet the evolving demands of modern electronics manufacturing, enabling high reliability and design flexibility.

High-Density Interconnects (HDI) PCBs

- Z-axis interconnects for high-layer-count boards.

- Microvia filling for fine-pitch designs.

- Superior yield and reduced process complexity.

System-in-Package (SiP) Assemblies

- Fine-pitch and high-density component assembly.

- Enhanced thermal durability and fatigue resistance.

- Compatibility with multiple assembly cycles.

Power Modules and Die Attach

- High thermal conductivity for IGBT modules and discrete components.

- Reliability under extreme temperatures and high-power conditions.

Our Product Line

Explore our portfolio of TLPS products tailored for various applications:

- PCB Z-Axis Interconnect Pastes:

- PCB-701: Microvia filling paste for z-axis interconnects.

- PCB-710: Advanced paste for high-layer-count PCBs.

- PCB-805: Thermal drain paste for high-heat dissipation.

| Typical Properties | PCB-701 | PCB-710 | PCB-805 | ||

| Product Design for | Via Filling Paste | Via Filling Paste | Thermal drain (PTH only) | ||

| Pre Sintered | Filler type | Cu and Sn-alloy | Cu and Sn-alloy | Cu & Sn-alloy | |

| Nominal Particle Size | um | <20 | <20 | <20 | |

| Viscosity @ 5rpm | kcps | 135 Brookfield TE Spindle | 380 Brookfield TE spindle | 450 | |

| Thixotropic Index | slope 1:10rpm | 1.4 | 3.5 | 5 | |

| Work Life @ 25℃ | Hours | >4 | >4 | 8 | |

| Storage Life <-10℃ | Months | 12 | 12 | 12 | |

| Post Sintered | Metal Loading | Wt % | 92 | 98 | 96 |

| Volume Resistivity | uΩ.cm | 50 | 35 | 30 | |

| CTE | ppm/℃ | 22 | 19 | 19 | |

| Thermal Conductivity | W/m.K | 50 | |||

- Component Attach Pastes:

- CAP-476-1: High-performance paste for component assembly.

- CAP-823-1: High-performance paste for fine-pitch assembly.

- CAP-824-3: Superior thermal durability for harsh conditions.

- APM-916-1: Dispensable paste for component assembly.

| Product | CAP-476-1 | CAP-823-1 | CAP-824-3 | APM-916-1 | |

| Target application | Component assembly | Fine pitch component assembly | High thermal durability assembly | Dispensable component assembly | |

| Fillar system | Sintering | Sintering (Cu, Sn-alloy) | Sintering (Cu, Sn-alloy) | Sintering | |

| Viscosity | CP51 2.5rpm, kcps | 55 | 210 | 190 | 50 |

| Nominal particle size | um | <20um | <33um | <20um | <40um |

| Method of application | Stencil Printing | 〇 | 〇 | 〇 | |

Dispensing | 〇 | 〇 | |||

| Volume Resistivity | (μΩ.cm) | 20 | 18 | 18 | 18 |

| Shear Strength | (kg/mm2)@25℃ | 4 | 4.2 | 4 | 3.6 |

(kg/mm2)@260℃ | 2.5 | 2.5 | 2.5 | 2.5 | |

(kg/mm2)@325℃ | NA | NA | NA | NA | |

| Applicable interface material | Au | 〇 | 〇 | 〇 | 〇 |

Ag | 〇 | 〇 | 〇 | 〇 | |

Cu | 〇 | 〇 | 〇 | 〇 | |

Ni | 〇 | 〇 | 〇 | ||

Sn | 〇 | 〇 | 〇 | 〇 | |

- Die Attach Pastes:

- DAP-481-1: Printable and dispensable for power modules.

- DAP-491-1: High thermal conductivity for discrete components.

| Product | DAP 481-1 | DAP 491-1 |

| Target Application |

| |

| Overall Product Features |

|

|

| Metal Loading (wt%) | 90 | 93 |

| Thermal Conductivity (W/m-K) | 31 | 52 |

| Viscosity (5.0 RPM CP-51, cps) | 21000 | 68000 |

| Thixotropic Index (0.5/5.0) | 3.6 | 2 |

| Slump test (minimum µm gap no bridge) | 200 | 150 |

| Stencil Life (hrs) | 8 | >8 |

| Die Attach Window (hrs) | 6 (die on LF) | 2 (die on LF) |

| 3×3 Au die on Cu LF X-ray void% | 10% | 10% |

| 3×3 Au die on Cu LF RT shear (kg/mm2) | 3.0 | 5.2 |

| 3×3 Au die on Cu LF 260C shear (kg/mm2) | 4.2 | 5.7 |

Technology You Can Trust

Ormet® TLPS technology is backed by rigorous testing and proven performance in demanding applications. These products are engineered to deliver unmatched reliability and functionality, helping you achieve your manufacturing goals with confidence.

Ready to take your electronics manufacturing to the next level? Contact us today to learn more about Ormet® TLPS products or to request technical support.

- Email: ormet@aitechnology.com