Solvent-Free, Water-Borne MOISTSEAL™ CC7650 Conformal Coating Provides Superior Corrosion Protection for Printed Circuit Boards

Balancing Performance and Costs of Manufacturing

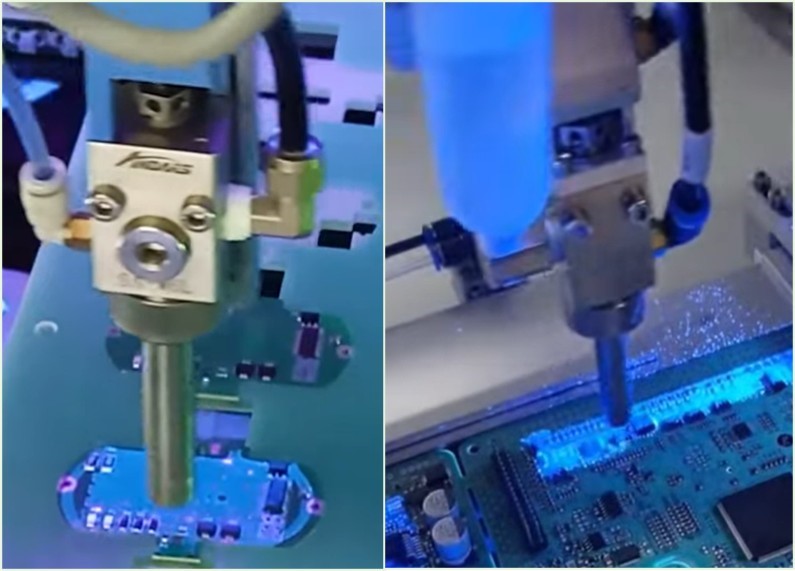

MOISTSEAL™ CC7650 is a game-changer for the corrosion protection of printed circuit boards in the electronics industry. It offers a more environmentally friendly and cost-effective solution. The water-borne formula eliminates the need for harsh chemicals and solvents, making it safer for the environment and workers. Additionally, it can be easily applied using standard spray equipment, reducing production time and costs. MOISTSEAL™ CC7650 is made of a novel polymer proven to be more than 100 times higher moisture and corrosive gases barrier than traditional acrylic conformal coatings. MOISTSEAL™ CC7650 approaches that of the PVDF polymer-based FLUOROSEAL® Conformal coating pioneered by AI Technology for the highest level of printed circuit board corrosion protection, including the most aggressive H2S gas-related dendritic corrosion. It dramatically lowered the costs with solvent-free ease of coating process. It is an answer to the drive for solutions that are both friendly to the environment and the works.

100 Times Better Corrosion Protection Than Solvent-Based Acrylic, Polyurethane, and Silicone Conformal Coatings

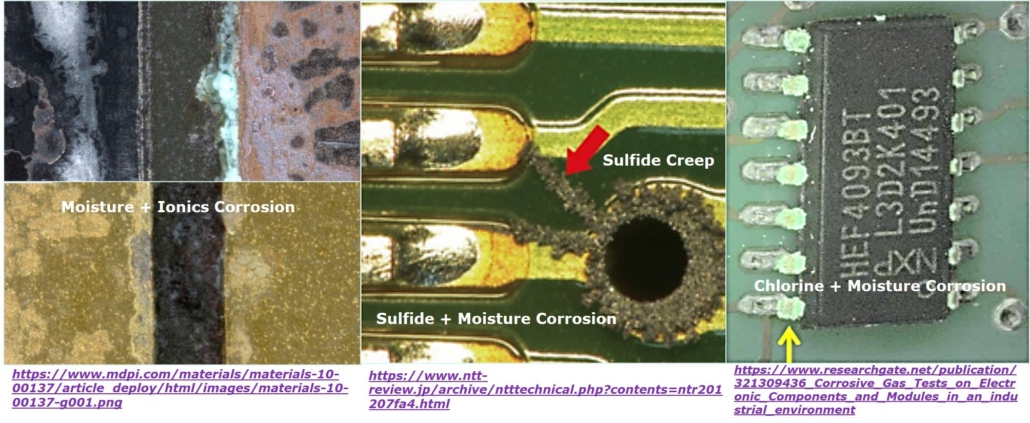

Corrosions in exposed base metal traces such as copper and nickel-plated contacts, solder interconnections, and plated through vias happen when there is condensed moisture laden with dissolved salts and ionic impurities, corrosive gases such as H2S, CO2, SO2, NO, Chlorine, etc. The function of the conformal coating for PCB board protection is to form a barrier to slow down and block these corrosive elements from penetrating and retaining at the board metal traces and coating interfaces.

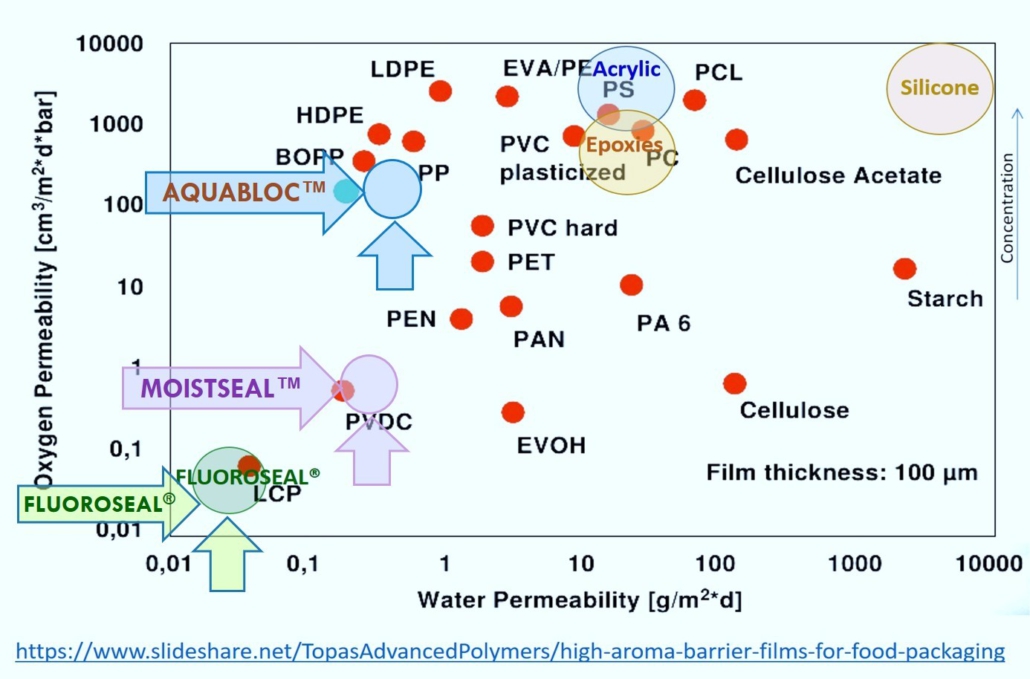

The effectiveness in protecting base metal traces from corrosion of a conformal coating depends on the coating in blocking or slowing down the penetration of water molecules and corrosive gases from penetrating through and getting to the metal traces. The faster or more permeable the conformal coating for the moisture, moisture with dissolved salts, corrosive gases, and moisture-water absorption to forming corrosive electrolytes at the coating and metal traces interfaces, the faster the corrosion of the PCB being protected.

The ability of the conformal coating to slow or block the penetration of moisture and corrosive gases is determined primarily by its molecular structures. For example, PET is used for bottling soft carbonated drinks because it is a relatively good barrier to carbon dioxide escaping from bottled drinks. PET plastic is used based on the balance of acceptable gas barrier, low health impact, and reasonable cost. PE and PP are not selected primarily because of the slightly higher permeability of gases such as oxygen and, thus, carbon dioxide.

MOISTSEAL™ CC7650 is made of a novel polymer proven to be more than 100 times higher moisture and corrosive gases barrier than traditional acrylic conformal coatings.

Corrosion Protection Approaching Performance of FLUOROSEAL PVDF Conformal Coating

MOISTSEAL™ CC7650 approaches that of the PVDF polymer-based FLUOROSEAL® Conformal coating pioneered by AI Technology for the highest level of printed circuit board corrosion protection, including the most aggressive H2S gas-related dendritic corrosion. It dramatically lowered the costs with solvent-free ease of coating process. It is an answer to the drive for solutions that are both friendly to the environment and the works.

If more stringent protection is needed after the application of the MOISTSEAL™ CC7650, a top coating with FLUOROSEAL® conformal coating can be applied to provide the needed extra protection against the aggressive environment of electronic devices that are later designated for use in those special operating environments.