View Products

Order some of our Solar related materials…

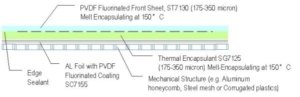

Innovative Melt-Encapsulating Thermal Back Sheet and PVDF Fluorinated Transparent Melt-Encapsulating Front Sheet Reduces Solar Panel Costs and Enhances their Performance

With the combination of a melt-encapsulating front sheet, a melt-encapsulating thermally conductive insulated metal back sheet with melt-bonding tabbing, a roll-to-roll lamination process or dramatically reduced time for vacuum lamination process at 140-160°C are now achievable goals. Much lower costs in both capital investment and solar panels is one of the end results in addition to high performance, conversion efficiency and long-term reliability.

With over 30 years of experience in formulating and manufacturing specialty materials and adhesives for electronic applications, AIT is proud to offer SOLARGRIP™, the industry’s first combination of PVDF fluorinated front and back sheets that also encapsulate the solar module of cells in a single melt-encapsulating process.

- SOLARGRIP™ uses polymer crystallites for strength in place of cross-linking EVA encapsulant to reduce the vacuum thermal forming cycle time by a factor of 5-10.

- The reduced cycle time directly contributes to reduced costs in manufacturing solar panels.

- The low moisture ingression afforded by the fluorinated PVDF and modified polyethylene enables self-sealing edges and the possibility of frameless panels.

- Outstanding compatible bonding with standard EVA encapsulant and cross-linkable polyolefin encapsulant.

By embedding fluorinated and thermally conductive melt-flow back sheets in the PVDF, the efficiency of conversion is improved in the hot summer sun. Other features include:

- SOLAR-IMB™ is the industry’s first insulated thermally conductive back sheet and encapsulant single ply laminate that helps to dissipate heat and lower the cell temperature.

- A UV and moisture protection encapsulating thermally conductive back sheet with PVDF back sheet layer protection.

- The effect of lowering the cell temperature from 70°C to 50°C will increase the efficiency from the already depressed value to 13-14% from the 10% at 70°C for typical mono-crystalline solar under the summer sun.

AIT’s solar solution for photovoltaic panel manufacturing also includes many enabling and complementary solutions:

- Melt-encapsulating transparent front sheet (SOLAR-THRU™) from 5-15 mils for thin film to mono-crystalline solar.

- PVDF front sheet for ultimate UV and moisture protection.

- Melt bonding fluorinated conductive tabs to reduce the tabbing temperature and the thickness from 8 mils to 3 mils.

- UV resistant fluorinated PVDF transparent coating reduces glare on glass front sheet.

All materials are RoHS, REACH and WEEE compliant in accordance with the UL94V-0 rating conferred on the AIT US manufacturing facility located in Princeton Junction, New Jersey.

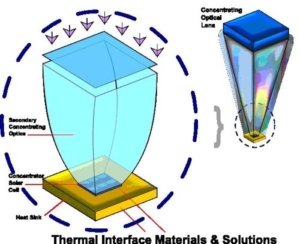

Other complementary material solutions from AIT include thermal management and anti-glare coating for concentrated photovoltaic (CPV) applications:

For a recommendation, information or assistance, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 and Fax: 609-799-9308