View Products

Order some of our Thermal Management related products…

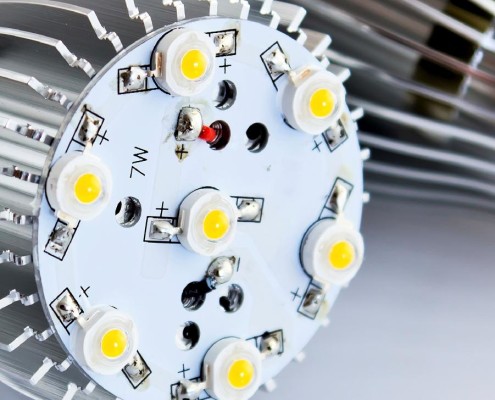

THERMAL INTERFACE MATERIALS FOR ROBUST LED LIGHTINGS, DISPLAYS AND PANELS: LED Die-Attach Adhesive, LED Submount Thermal Adhesive, LED Module Mounting Compressible Thermal Interface Phase-Change Pad

- LED Die-Attach Adhesive with proven high Thermal Conductivity and Low Thermal Interface Resistance

- LED Submount and LED Module mounting Thermal Film Adhesive with Instant Melt-Bonding

- Compressible, Conformal Phase-Change Thermal Interface Pad for LED Heat-Sink

- Insulated Metal Thermal Substrate for Metal-Core Printed Wiring Board (MCPCB) with 2X Thermally Conductivity for LED Submout and LED Module

What distinguishes AIT LED total thermal management material solutions besides the unparalleled and proven low thermal resistance in the die-attach, sub-mount and heat-sink are the long-term reliability and consistent performance after years of thermal shock and cycling with the build-in stress relief, and molecular structures that are engineered to prevent “drying” or cracking inside the materials and along the interface surfaces.

- Ultra-low electrical and thermal resistance between LED dies and sub-mount or substrate. High mechanical strength and glass transition temperature to enable fast wiring bonding as high as 275°C.

- For sub-mounting, molecular flexibility is specifically engineered in the thermal adhesive to provide stress absorption even in the most mis-matched CTE substrates and surfaces that extend to below -55°C. Depending on the assembly process, LED sub-mounting has a choice of novel and the only proven pressure sensitive thermal adhesive or a melt-bonding thermal adhesive film.

- In the heat-sink interface layer, AIT provides the patented and proven compressible and conformable interface pad to eliminate trapped air and accommodate irregularity in gap that need to be filled.

- Ultra-low moisture absorption and sensitivity

- RoHS, REACH and WEEE compliant that meets UL94V-0 rating.

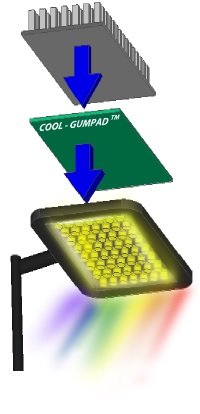

COOL-GUMPAD™: A gum-like Compressibility up to 3 times the original thickness to fill in all uneven and unparallel thermal interface surfaces for LED luminaire module, large area power module and large area metal-core printed wiring board (MCPWB) Applications. It is a new This new generation of compressible phase-change pad is patented (US Patent 6,496,373) and provides both compressibility and conformability with phase-change to achieve the best of thermal grease performance. Side-by-side comparative performance measurements in comparison by directly replacing standards pads find in LED luminaire lighting modules to AIT COOL-GUMPAD, the temperature is lower the temperature by 10-20% from heat-sink to module junction temperature from 60°C to less than 56°C.

Properties of COOL-BOND™ Die-Attach for LED Device Applications

| PROPERTY/PARAMETER | ME 8512 | ME 8638-UT | ME 7519-LB |

| Electrical Resistivity | <0.0003 ohm-cm | <0.0003 ohm-cm | >10¹⁴ ohm-cm |

| Viscosity @5.0 rpm/Thixotropic Index | 10,000 cps/4.0 | 10,000 cps/4.0 | 20,000cps/>3 |

| Glass Transition Temperature (°C) | 52 | 90 | 52 |

| Device Push-off Strength (psi) | >3000 | >3000 | >3000 |

| Hardness (Type) | ~ 80 | ~ 90 | ~ 85 |

| Cured Density of Conductive Adhesive Portion (gm/cc) | 4.0 | 4.6 | 2.5 |

| Thermal Conductivity | > 12.0 W/m-°K | > 12.0 W/m-°K | > 12.0 W/m-°K |

| Linear Tab-Composite Thermal Expansion Coefficient (ppm/°C) | 40 (X-Y=Z, Isotropic) | 38 (X-Y=Z, Isotropic) | 45 (X-Y=Z, Isotropic) |

| Maximum Continuous Operation Temperature (°C) | > 180 | > 180 | > 180 |

| Decomposition Temperature @5% weight loss (°C) | >450 | >450 | >450 |

| Recommended Curing Temperature/Time (°C/min.) | >175/10 | >175/10 | >175/10 |

Extreme Thermal Adhesive for Module Sub-Mounting

- Instant Bonding Compressible Pressure Sensitive Adhesive Pad

- Melt-tacking and In-situ Curable Low Thermal Resistance Film Adhesive

- Proven Lower LED Junction and Device Temperature for Higher Brightness

| Module Sub-Mounting Thermal Adhesives | |||

| PROPERTY/PARAMETER | RTK 7555 | RTK 7554 | ME 7519-LB |

| Thermal Conductivity | > 0.2 W/m-°C | > 0.2 W/m-°C | > 0.2 W/m-°C |

| Dielectric Strength (Volts/mil) | >550 | >300 | >750 |

| Device Push-off Strength (psi) | >1000 | >1000 | >1000 |

| Cured Density (gm/cc) | 2.5 | 2.5 | 2.5 |

| Thermal Conductivity | > 3.0 W/m-°C | > 8.0 W/m-°C | > 12 W/m-°C |

| Maximum Continuous Operation Temp. (°C) | > 150 | > 150 | > 150 |

| Electrical Resistivity | >10¹⁴ ohm-cm | >10¹⁴ ohm-cm | >10¹⁴ ohm-cm |

Compressible Phase-Change Thermal Interface Pads

- Compressible and conformal couples with phase change to allow elimination of voids

- Proven for most stringent applications including military applications

- US patented innovation

- Non-silicone and non-contaminating

Compressible Thermal Gap Pad Thermal Interface

- Compressible and conformal

- Proven for large area requiring thermal filling into height gaps of different components

- Ideal for large area display and module to device enclosure

- Proven and used for most critical thermal challenges with military grade reliability

- Non-silicone and non-contaminating

- Available with different thickness with one-side or both side pressure sensitive

| Other AIT Thermal Interface Materials for HB LED Applications | ||

| FUNCTION | AIT PART # | THERMAL, ELECTRICAL AND OTHER RELEVANT PROPERTIES |

| Compressible Phase-Change | COOL-SILVER™ PAD CPR8850-LB |

|

| Compressible Phase-Change | COOL-SILVER™ G3 PAD |

|

| Compressible Phase-Change | COOL-PAD™ CPR7158 |

|

| Compressible Phase-Change | COOL-PAD™ CPR7155-LB |

|

| Gap-Filling Thermal Pad | COOL-GAPFILL™ DT, TT |

|

| Compressible Gel-Film | COOL-GELFILM™ SZ |

|

| Thermal Grease | COOL-SILVER™ G3 Grease |

|

| Thermal Grease | COOL-GREASE™ CGR7559-LB |

|

| Thermal Gel | COOL-SILVER™ G3 Gel |

|

| Electro-Grease | COOL-GREASE™ CGR8550 |

|

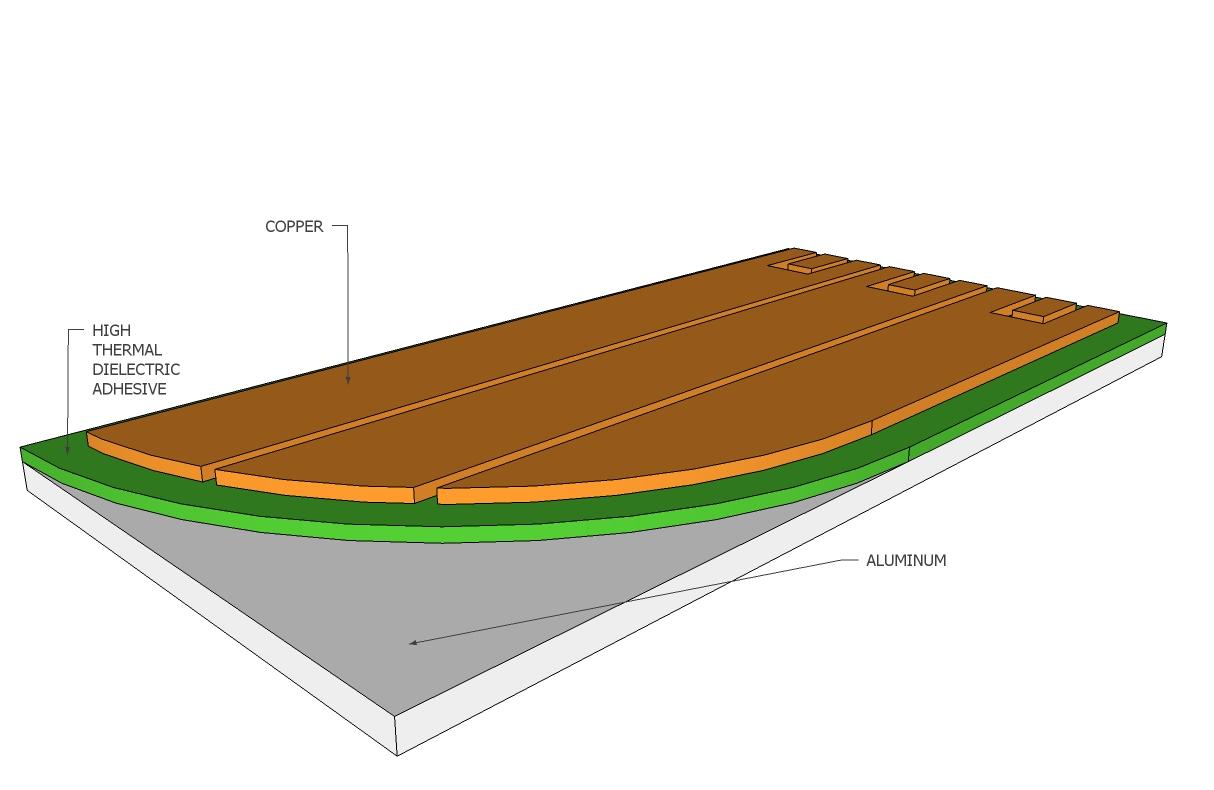

Insulated Metal Thermal Substrate and Pre-Preg Thermal Film Adhesive for LED Sub-Mounting & Module:

- Measured 2x thermal conductivity to that of traditional insulated metal substrates

- Notable improvements in the reliability of such larger area LED panel

AIT patented thermal management technologies (US patent# 7,154,046; 6,717,819; 6,580,035; 6,581,276; 6,108,210; 6,297,564; 6,665,193; 6,973,716) give unparalleled thermal and reliability performance, and is different from the traditional insulated metal substrate in the following :

- Instead of a rigid fiberglass thermally conductive epoxy laminate, we use our proprietary self-supporting thermal dielectric insulating layer resulting in stress-free and warp-free thermal copper-clad laminates.

- Unparalleled thermal conductivity in the insulating layer by eliminating the fiberglass fabrics.

- High temperature stability to withstand soldering at 300°C.

- Multi-layer capability with the same flexible dielectric copper-clad pre-preg that can be laminated at less than 15 psi pressure and at 125°C or higher.

- Base metal plates with choice of aluminum and copper thicknesses.

- Thinner insulated metal substrate and pre-preg are available in rolls of 12-24-inch width.

- Thicker insulated metal substrate and pre-preg are available in sheets of 24-inch or wider.

- Unparalleled adhesion to copper and aluminum even without chemical etching or treatment.

- Ideal for power and LED components, modules and panels.

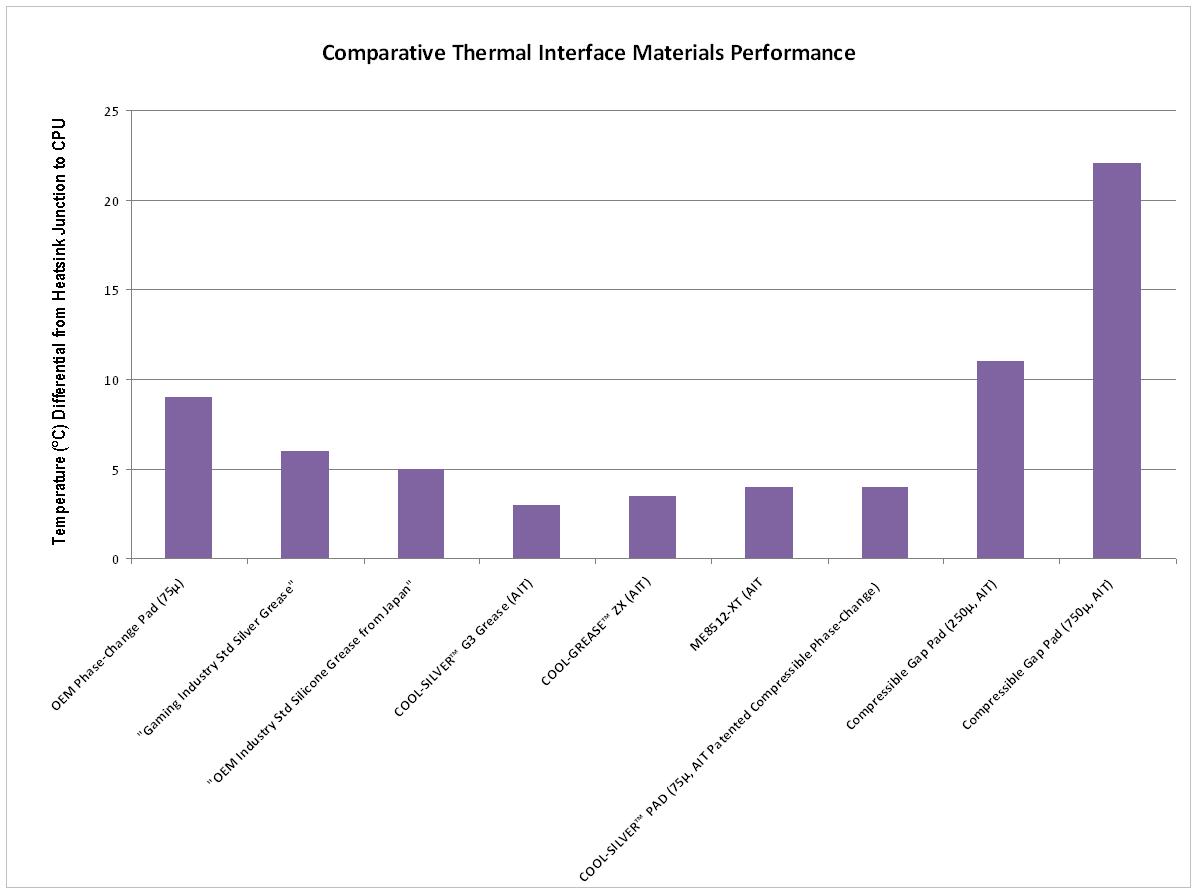

The following is a comparative measurements of various thermal adhesives and thermal interface materials demonstrating drastic difference is performances depending on the material characteristics and ability to eliminate trapped air along the thermal interfaces.

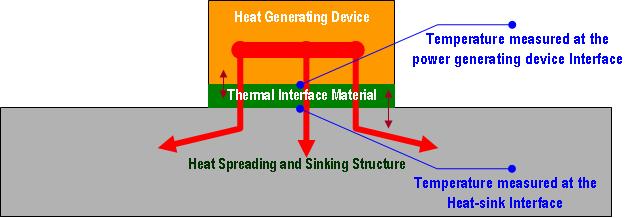

Comparison of Thermal Interface Materials Performance: Lower temperature rise represents a measurement of the efficiency of the thermal interface materials in transferring heat generated by the power electronic device to the heatsink (with fan) that dissipates heat to the environment by the forced circulating air. The thickness of the thermal interface material also contributes significantly to the efficiency of heat dissipation and should be minimized as much as the physcial configuration or construction permits. The effectiveness of a specific thermal interface material cannot be easily predicted by the claimed or even measured bulk thermal conductivity data or value: the thermal resistance at the thermal interface material to the substrates in their respective interfaces for thin bondline or interface thickness are significant and represents the “coupling efficiency” that cannot be predicted and must be measured.

The data in the comparison of thermal interface materials are collected by using an Intel CPU and forced air heatsink as represented in the above configuration. A thermocouple is drilled and embedded at the heatsink junction that interface with the thermal interface material to provide direct temperature data at the interface for measuring the “coupling” of the specific thermal interface materials to the heatsink.

For more information and recommendation assistance, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or 1-800-735-5040 (EST) and Fax: 609-799-9308