Solderable Flexible Circuit Materials For Fine-Pitch And Super-Fine Pitch Flexible Circuit Applications

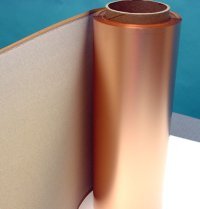

AI Technology has developed a solderable, organic copper-clad laminate flexible circuit substrate materials that can be used at temperatures as high as 300°C. The standard flexible circuit material uses 1 oz copper on this non-polyimide proprietary molecularly flexible material for a total 3-mil thickness as flexible circuit substrate. These flexible circuit materials are available with 1/4 or 3/8-oz copper for super fine-pitch flexible circuit applications of less than 1-mil line/spacing and via.

COUPLER™ Flexible Circuit Material Characteristics:

- Proprietary organic copper-clad laminate material with low dielectric constant, 3.0 @ 1 KHz with less than 0.01 dielectric loss and high insulation strength (>1000VDC/3-mil thickness).

- Non-silicone and non-contaminating molecularly flexible dielectric layer.

- Withstands chemical etching and wet chemical treatments for all PWB/PCB processes.

- Maintains outstanding flexibility even at temperatures of as low as 40°C.

- Eliminates traditional polyimide flexible circuit material “measling” and other moisture induced degradation and reliability problems as usually associated with polyimide based circuit boards.

- Outstanding moisture resistance, less than 0.3%, while maintaining high electrical and mechanical performance.

- UL-94-V0 fire-retardant rating.

- Same circuit density and design rules as traditional FR-4 and BT board.

- Lower temperature multi-layer flexible circuit processing from as low as 125°C.

- Solderable flexible circuit applications at 50% of the traditional polyimide flexible circuit material substrate cost.

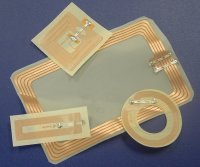

Applications:

- Organic copper-clad laminate substrate flexible circuit materials to replace polyimide and PTFE.

- Flex tape for area-array flexible circuit and interposer substrate.

- Flip-chip on flex with superfine pitches.

- Directly solderable flat and flexible jumpers.

- Flat and flexible cabling that can be used in class

- Solderable membrane switches and circuits.

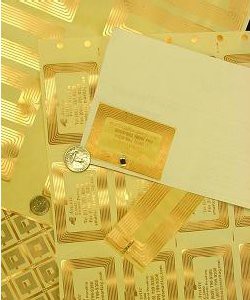

- Roll-to-roll or panel processing.

- Available in rolls of various lengths and width.

AIT COUPLER™ organic copper-clad laminate flexible circuit substrate and flexible circuit pre-preg material panels can be handled in exactly the same method and infrastructure as commonly used in standard PWB and flex circuit.

1. Panel & Roll Material Handling

- COOL-CLAD™ and COUPLER™ organic copper-clad laminate flexible circuit substrates can be stored in ambient conditions for at least 12 months.

- COUPLER™ flexible circuit pre-preg material can be stored in ambient conditions for at least 6 months.

2. Panel Prep

- Tooling/Registration

- Scrubbing

- Chemical Cleaning

- Base Metal Protection

3. Imaging

- Dry Film Application

- Wet Film Application

- Screened Image Application

4. Wet Chemistry Processing

- Etching

- Stripping

- Post Etch/Strip Clean

5. Solder Mask Application

- Screen, Spray or Curtin Coat

- Thermal Solder Mask

- UV Cured Solder Mask

6. Second Step Drill or Punch

- Punch

- Drill

- 7. Finishing Operation

- HASL

- OSP

- Tin

- Ni/Au

8. Finishing Fabrication

- Route

- Score

- Punch

| Characteristics | Unit | Conditioning | Typical Values | Specification | |

|---|---|---|---|---|---|

| Volume Resistivity | M&-cm | C-96/35/90 | 5X108~5X109 | 106 | |

| Surface Resistivity | M& | C-96/35/90 | 5X106~5X107 | 10t | |

| Permittivity 1 MHz | – | C-24/23/50 | 3.8-4.2 | 5.4 | |

| Loss Tangent 1 MHz | – | C-24/23/50 | 0/013-0.020 | 0.035 | |

| Arc Resistance | Sec | D-48/50 + D-0.5/23 | 100 | 60 | |

| Dielectric Breakdown | KV | D-48/50 | 45 | 40 | |

| Moisture Absorption | % | D-24/23 | 0.01-0.20 | 0.35 | |

| Flammability | – | C-24/23/50+E-24/125 | 94V0 | 94V0 | |

| Peel Strength 1oz | Lb/in | 288°C Solder Floating | 8 | 8 | |

| Thermal Stress | Sec | 288°C Solder Dipping | 600 | 300 | |

| Pressure Cooker (2 atm/120°C) | hr | hr | Sec | 288°C Solder Dipping | 300 |

| 1 hr | Sec | 288°C Solder Dipping | 300 | N/A | |

| 2 hr | Sec | 288°C Solder Dipping | 300 | N/A | |

| Flexural Strength | LW | psi | A | 6000 | 60000 (N/A, For Flex Circuit) |

| CW | psi | A | 5000 | 60000 (N/A, For Flex Circuit) | |

| Dimensional Stability X-Y Axis | % | E-0.5/170 | 0.01-0.020 | 0.050 | |

| Coefficient of Thermal Expansion | Z-axis below Tg | In/in/°C | TMA | 60 PPM | N/A |

| Z-axis above Tg | Z-axis above Tg | In/in/°C | TMA | 180 | N/A |

| Glass Transition Temperature | °C | DSC | -40 +/- 5 | N/A |

For more information and recommendation assistance, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 and Fax: 609-799-9308