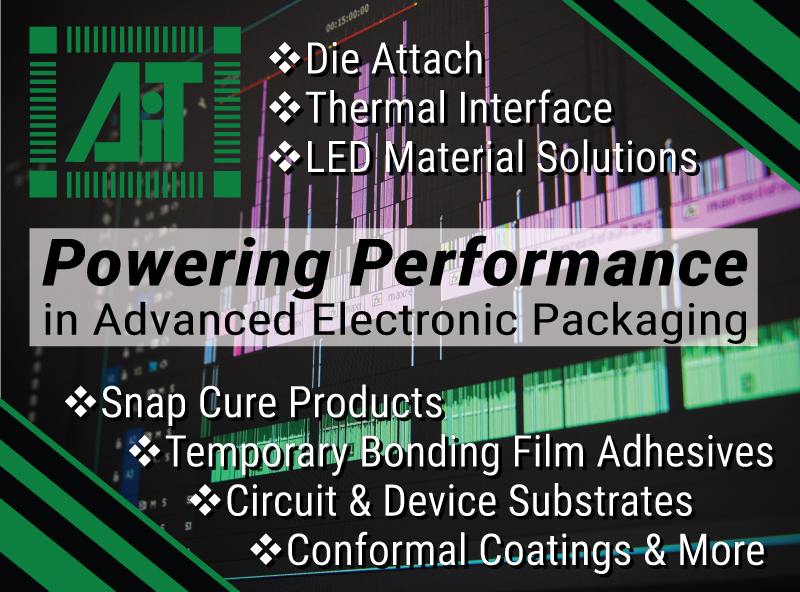

Thermal Interface Materials

Learn More• Proven best performing thermal greases and gels

• Patented compressible phase-change pads

• Industry standard thermal pressure sensitive adhesivesSpecialty Grinding and Dicing Tape and Media

Learn More• High Temperature Dicing and Grinding Tapes

• UV and Heat Releasing Dicing and Grinding Tapes

• Heat-Sliding and Solvent Separation Spin-Coating Liquid Wax and Film AdhesiveCircuit and Device Substrates

Learn More• Insulated Metal Thermal Substrate and Prepreg for Multilayer MCPWB

• Insulated Flexible Copper Substrate and Prepreg for Multilayer Ultrafine Line Circuits

AI Technology, Inc. is proud to announce that we have been named a Gold Supplier by BAE Systems for 2022.

“It’s unquestionably THE BEST thermal compound/grease I’ve ever used.”

“It does what it says”

“Effective as a heat sink compound”

AIT PRIMA-PROTECT stands out from the competition:

AIT engineering, sales and product support:

1-609-799-9388 or 1-800-735-5040

Fax: 609-799-9308

Dicing and Grinding Tapes & Greases

Die-Attach Paste and Film Adhesives

Thermal Adhesives and Interface Materials (TIM)

Insulated Metal Substrate and Metal Core Printed Substrates

AIT Brochure Of Insulated Metal Thermal Substrate (IMTS)

Flip-Chip and Specialty Adhesive Materials

Substrate & Component Attach Paste and Film Adhesives

Solderable Flexible Circuit & Interposer Substrate

MIL-STD 883C Method 5011.4 Compliant Adhesives

NASA and ESA Outgassing Compliant Adhesives

UV Resistant Coating, High Temperature Tape Adhesives and Labels

ABOUT US

AI Technology has more than 29 years experience in designing and manufacturing various forms of high performance “Stress-free” flexible adhesive films and pastes and materials for microelectronic packaging and thermal interface materials for thermal management applications. Our newest research has yielded higher performance and lower cost, solderable flexible circuit substrate materials to replace polyimide-based organic copper-clad laminates in high frequency, RFID, and with low dielectric constant loss and low moisture absorption in replacing PTFE substrate material in microwave circuits. Our technologies and products include solvent-free dies and substrate attach pastes and films, compressible gap-filling phase change thermal interface materials of thermal pads, thermal gels, thermal greases, polymer based Solder-Sub® flexible conductive adhesives for solder-replacement in fine-pitch interconnections, near-hermetic lid sealant for ceramic and metal covers and optical glass lids for opto-electronic sensors and devices, EMI Shielding gasket/adhesive/caulk materials, double-sided UV-release wafer grinding tapes and high temperature-static free dicing tapes.

OUR HISTORY

Since pioneering the use of flexible epoxy technology for microelectronic packaging in 1985, AI Technology has been one of the leading forces in development and patented applications of advanced materials and adhesive solutions for electronic interconnection and packaging. AI Technology now has one of the highest reliability adhesives and underfills for die bonding for the largest dies, stack-chip packaging with dicing die-attach film (DDAF), flip-chip bonding and underfilling and high temperature die bonding for single and multiple-chip modules for applications beyond 230°C. The company continues to provide the adhesive solution for component and substrate bonding for both military and commercial applications. Its thermal interface material solutions of patented phase-change thermal pads, thermal greases and gels and thermal adhesives set many bench marks of performance and reliability for power semiconductors, modules, computers and communication electronics.

The company has an ISO9001:2008 certified manufacturing and R&D facility in the U.S. and a Far East Center in Hong Kong. The US headquarters has more than 50,000 square feet of manufacturing facilities for its die and substrate attached adhesive films and pastes, thermal interface materials (TIM) including insulated metal substrates, gap-filling compressible phase-change pads, thermal gels, thermal greases and adhesive films and pastes. AI Technology provides electromagnetic and radio frequency interference (EMI/RFI) mitigation material solutions including conductive gaskets, form-in-place (FIP) conductive gaskets, self-attached shielding covers/cans/lids, conductive caulks and adhesives, ultra-high temperature (300°C) continuous use films and paste die and component adhesives and advanced organic copper-clad laminates from 1/4 oz to 1 oz copper within its 16-acre campus in Princeton Junction, NJ.

AIT application engineering, sales, chemists, and material scientists are ready to design and manufacture to your application’s requirements and specifications. Please inform us of your requirements using the Contact tab or click on the button below:

AIT sales and product support:

1-609-799-9388

Fax: 609-799-9308